Since Kirby supported his point of view I felt compelled to do the same.

I would rather have a mind opened by wonder than one closed by belief, so I copied this information.

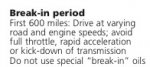

Pad break-in, is a subject that is too often misunderstood, and is prone to a variety of opinions and approaches. Contrary to the belief of some installers and DIYers, on-vehicle pad bedding is not designed to cure the pads (since post-cure is already performed during production providing the pads are sourced from a quality-oriented maker). Rather, the on-vehicle bedding is intended to mate the new pads to the rotors. In use, a transfer of material occurs between the pad and rotor surfaces, conditioning the rotors micro-finish. In effect, the initial pad/rotor break-in serves to help stress-relieve the rotors, creating a compatible pad/rotor package. If pads are subjected to high temperature and pressure too quickly, pad friction material might glaze and harden, reducing the braking effectiveness and shortening pad life.

We spoke with a select number of industry brake experts for their opinions regarding the importance of pad and rotor mating.

According to Wagners Eric Smith (one of Wagner’s brake systems instructors at its World Training Center in St. Louis), “When you bed brake pads, your not performing a post-curing, since this is already done at the factory. What you are attempting to do is to transfer material between the pad and rotor, in order to smooth-out the rotors machined surface (the peaks and valleys). You'll want to perform this material transfer as smoothly as possible. Especially on semi-metallic pads, we want this material transfer to equalize the surfaces so they're as compatible as possible. Your goal is to achieve a nice mirror finish on the rotors.Remember, a smooth rotor surface does not mean that glazing has occurred. The rotors are supposed to arrive at a smooth finish.“

Per Stan Kulis, Director of Research at Abex Friction Products, “We heartily recommend the ‘bedding-in’ process for all applications from standard passenger cars to emergency vehicles.“ While bedding is important for improving performance and wear of the pad, “the bedding process is also critical in the conditioning of the rotor (especially if its been turned) and in establishing the all-important transfer film(between pad and rotor). Pad bedding is needed for all types of pads (i.e.non-asbestos organic, semi-metallic, carbon-metallic, ceramic metallic,etc.).

Under-utilization of the brake pads without proper bedding will slow the overall process considerably and, depending on the material type, encourage glazing of the area in contact and enhance the propensity for brake noise. Over-use of an unconditioned system will affect the organic constituents of the composition the most. A phenomenon called green fade will occur as the pads are surprised with the sudden surge of energy. The driver will feel his pedal efforts increase significantly (possibly to the floor). Brake odor and smoke could also occur. Any of these conditions should be a signal that something is amiss. Depending on the severity of the condition, the driver may experience either an increase in material effectiveness, if surface burnout has occurred; or a decrease in effectiveness if heavy glazing has developed. Noise may accompany either situation.

If YOU wonder where I copied this information from,

click here.

I would rather have a mind opened by wonder than one closed by belief, so I copied this information.

Pad break-in, is a subject that is too often misunderstood, and is prone to a variety of opinions and approaches. Contrary to the belief of some installers and DIYers, on-vehicle pad bedding is not designed to cure the pads (since post-cure is already performed during production providing the pads are sourced from a quality-oriented maker). Rather, the on-vehicle bedding is intended to mate the new pads to the rotors. In use, a transfer of material occurs between the pad and rotor surfaces, conditioning the rotors micro-finish. In effect, the initial pad/rotor break-in serves to help stress-relieve the rotors, creating a compatible pad/rotor package. If pads are subjected to high temperature and pressure too quickly, pad friction material might glaze and harden, reducing the braking effectiveness and shortening pad life.

We spoke with a select number of industry brake experts for their opinions regarding the importance of pad and rotor mating.

According to Wagners Eric Smith (one of Wagner’s brake systems instructors at its World Training Center in St. Louis), “When you bed brake pads, your not performing a post-curing, since this is already done at the factory. What you are attempting to do is to transfer material between the pad and rotor, in order to smooth-out the rotors machined surface (the peaks and valleys). You'll want to perform this material transfer as smoothly as possible. Especially on semi-metallic pads, we want this material transfer to equalize the surfaces so they're as compatible as possible. Your goal is to achieve a nice mirror finish on the rotors.Remember, a smooth rotor surface does not mean that glazing has occurred. The rotors are supposed to arrive at a smooth finish.“

Per Stan Kulis, Director of Research at Abex Friction Products, “We heartily recommend the ‘bedding-in’ process for all applications from standard passenger cars to emergency vehicles.“ While bedding is important for improving performance and wear of the pad, “the bedding process is also critical in the conditioning of the rotor (especially if its been turned) and in establishing the all-important transfer film(between pad and rotor). Pad bedding is needed for all types of pads (i.e.non-asbestos organic, semi-metallic, carbon-metallic, ceramic metallic,etc.).

Under-utilization of the brake pads without proper bedding will slow the overall process considerably and, depending on the material type, encourage glazing of the area in contact and enhance the propensity for brake noise. Over-use of an unconditioned system will affect the organic constituents of the composition the most. A phenomenon called green fade will occur as the pads are surprised with the sudden surge of energy. The driver will feel his pedal efforts increase significantly (possibly to the floor). Brake odor and smoke could also occur. Any of these conditions should be a signal that something is amiss. Depending on the severity of the condition, the driver may experience either an increase in material effectiveness, if surface burnout has occurred; or a decrease in effectiveness if heavy glazing has developed. Noise may accompany either situation.

If YOU wonder where I copied this information from,

click here.